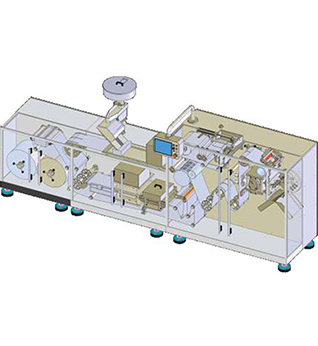

Model NT 300

Applications:

Technical Specifications:

| Specification | Value |

| Max Foil Width | 300 mm |

|---|---|

| Max Forming Advance | 240 mm |

| Base Film Thickness Max | 0.25 mm- 0.3 mm |

| Lid Foil Thickness Max | 0.02 mm - 0.04 mm |

| Forming Area | 200 mm x 234 mm |

| Speed | 40 Cycles/min (Cold Forming) |

| 50 Cycles/min (Thermo Forming) | |

| Max Forming Depth | 12 mm |

Product Details :

Features:

- The machine is suitable to produce blisters with various foils like PVC, PVC/PVDC, PET, COC, ACLAIR, and and ALU/ALU types of material for forming the blister cavities. The machine offered will not have an alu/alu facility,, as this was not needed currently for the pack design submitted.

- The machine is suitable to pack both tablets and capsules.

- The machine is a flat-forming and rotary-sealing model.

- Care taken to clean the film while in transport. in the machine.

- The web clamping system is designed to ensure that the web does not reverse.

- Product feeding is designed based on product shape, and in the current format designed, it will be a shutter gate feeder.

- Care is taken in such a manner that there is no cross-contamination on product feeding. Change parts can be fitted with minimum tools.

- Trim is cut and collected in a a separate box.

- The machine has a print registration control system inbuilt.

- Sealing is rotary sealing and produces the the best quality of seal without any leak issue.

- An embossing and perforation station is available.

- The machine has four servo motors for product feeding, web indexing, punch indexing, punching, and picking and placing blisters

- Safety guards are made elegant for easy operation support.

- HMI carries three-level password control and can be assigned to individuals as per the need.

- The NFD option according to the need can be integrated.

- Blister machine carry rotary pick and place system for holding the blister and delivering on the conveyor smoothly the completed blister pack.

- The machine is built with a batch code printing unit.